Since we are developing the latest Copter cheerleading shoes recently, I came to our shoe factory to participate in the entire process of development and proofing again . Let me share with you the entire process of making shoes in easy-to-understand terms~

1.「last」

The last master polishes the last of the shoe according to the designer's drawings/original shoe/shoe diagram. The first version of the last is made based on this last and a sample shoe is tried on the foot. After that, the last is adjusted in areas where the foot feels bad. This process is repeated until the sample shoe is comfortable. !

This is particularly demanding for last makers. There are many shoes with more complicated shoe shapes that require several months of adjustment by strict craftsmen.

2.「Hand drawn template」

The last master determines the last and takes it to the master who draws the template. According to the last, the master uses cardboard or plastic sheets with a certain thickness to draw each part of the shoe that fits the last. After cutting it, bagging it and handing it over to the master who cuts the material.

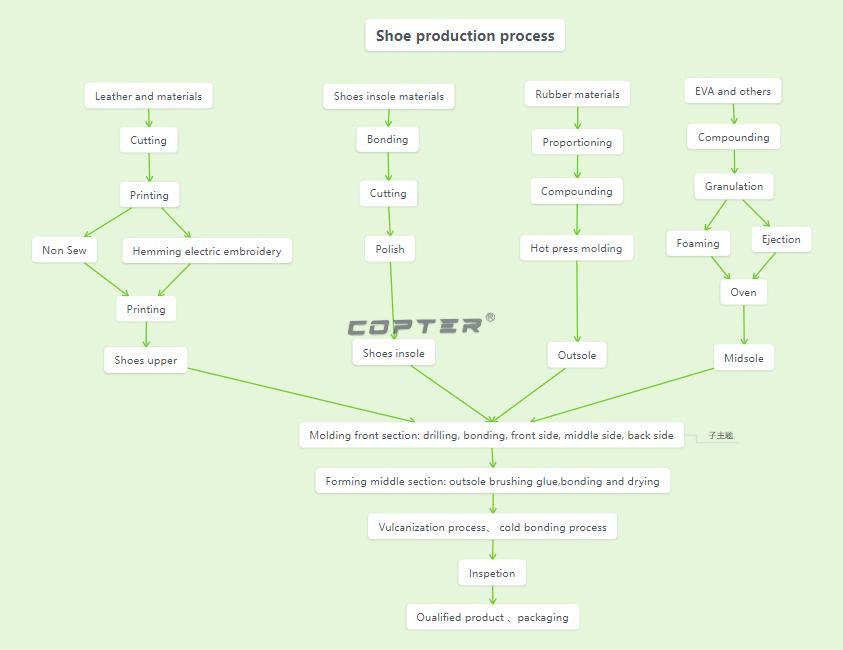

3.[ Cutting ]

Cutting is when the master divides a whole piece of leather into template-sized pieces and distributes them to the assembly line workers in bags and bags. First-class factories will use a combination of manual + machine cutting; most factories use molds to draw manual cuts and bags on the leather piece by piece.

4.「Shoe Assembly」

I got this name to make it easier for everyone to understand. It means that the assembly line masters sew the cut parts together with the lasts, viscose, take them to the machine to bake and shape, and press the soles... to ensure the stability of the shoes and the beauty of the shoe shape.

5.[ Sole ]

Common sole materials include rubber, EVA, PU, MD, TPR, etc. Each of these materials has its own properties and is often used to produce shoes with different functions.

Of course, sometimes manufacturers will combine different materials to achieve the effect of 1 + 1 > 2.

6.「Fabric」

Choose the correct fabric for pattern making and the shoe type is OK. We will organize the shoe-related information into a file bag to ensure that each pair is consistent and there will be no batch problems.

7.「Mass production」

Mass production based on pattern-making sample shoes

Contact: Damon

Phone: +86-15391860686

Tel: +86-15391860686

Email: damon@coptercheer.com

Add: Building 28th ,Phase 4 ,economic development area, Zhangjiajie City, Hunan ,China

We chat